> Wuhan Golden Phoenix Paper is an entity enterprise specializing in the production of industrial packaging paper, currently has two production bases in Wuhan city and Xiao Gan city, can provide from 60g/㎡ to 170g/㎡ high-strength corrugated base paper full specifications, a full range of products, is the largest professional manufacturer of "high-strength corrugated base paper" subdivision products in China.

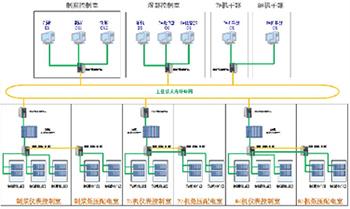

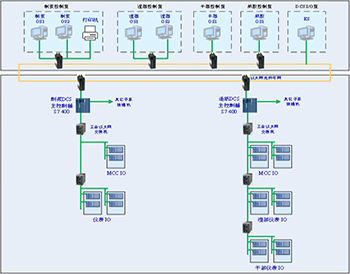

> The project contains one pulping line and two paper process line (7A, 7B)

> We also provide a complete DCS control system for the other production lines for this corporate.

● Wuhan Jinkou Base Phase I (paper Machine line No.1)

● Wuhan Jinkou Base Phase II (paper Machine line No.2)

● Wuhan Jinkou Base Phase III (paper Machine line No.3 and No.5)

● Xiaogan Base Phase I (paper Machine line No.6)

● Xiaogan Base Phase II (paper Machine line No.7 and No.8)

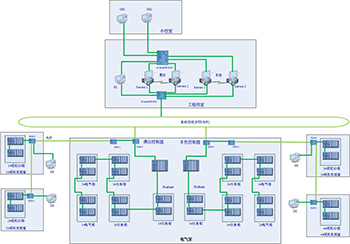

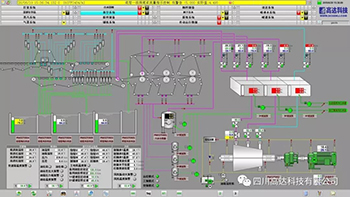

> Sichuan Fengsheng Paper Technology Co., Ltd., founded in 1999, is the pioneer of the bamboo forestry-pulp-paper integration in Southwest China. The leading products are as follow: bleached and natural color bamboo pulp paper, bleached and natural color bamboo household paper, hillside brand facial tissue, jumbo roll, pocket facial tissue, kitchen paper towel and other finished products.

> Project size:

● Phase I is two pulp lines and four crescentiform tissue machines. control point: 2560.

● Phase II is one pulp line and four crescentiform tissue machines. control point: 2070.

● Phase III is one pulp line and six crescentiform tissue machines. control point: 3000.

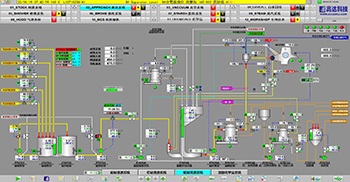

> Xinxiang Xinya Paper Group Co., Ltd., is an enterprise group mainly engaged in pulp and papermaking, integrating heat and power cogeneration, pharmaceutical and chemical engineering, logistics and trade, machinery manufacturing, forest base development and environmental protection. It is the leading enterprise in the papermaking industry in Henan Province.

> this project contains one coated paperboard.

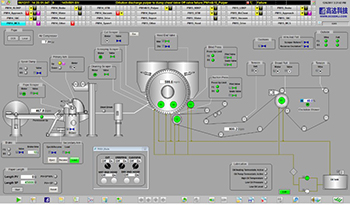

> provide them with DCS + MCS configuration and control solutions.

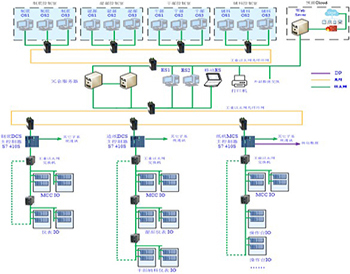

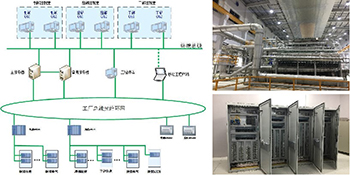

> Weihai Longgang Paper Co., Ltd., ,one of the top ten industrial investment projects in Weihai city in 2019,is important industrial packaging supporting factory in Jiaodong area, China.

> PM1 DCS project, providing by Gaoda, is smoothly operating more than six years.

> under this cooperate foundation, we provide user with complete DCS control system and drive system, which annual output of 300,000 tons of pulp and papermaking, for PM2 project.

> Rizhao Huatai Paper Co., Ltd. is a subsidiary of Huatai. Founded in 1969, it is a large-scale papermaking enterprise integrating pulp, paper and paper processing. The Rizhao Huatai Chemical Pulp and Paper project, which is a encourage investment project by the national industrial policy, is started construction on Haiyou Economic Development Zone, Rizhao City, Shandong Province. Sichuan Gaoda Sci&Tech provides a complete set of DCS proposal, supply, commissioning and service.

> Yueyang Forest & Paper Co., Ltd., subsidiary of China Paper Investment Co., Ltd., is the only one forestry-pulp-paper integration as the main business of national enterprise defined by SASAC, and is the first SASAC’construction specification board and asset management pilot enterprise. From the founding of 1956 to 60 years of enterprise through the ups and downs of the future direction of development, it has developed into a listed company with total assets of 21.5 billion yuan, annual production capacity of paper and commercial pulp of 1.9 million tons (Yueyang base:800,000 tons), and self-operated paper forest base of nearly 2 million mu., comparing with the production scale was 34,000 tons/year in 1956.

> Vietnam Thuan An Production Company/Limited firstly responds to the Belt and Road in southern Vietnam. This project adopts fully integrated domestic equipment, and is the largest multi-functional waste paper recycling papermaking machine in southern Vietnam.

> The project includes one packaging production line and its public supporting works.

> Gaoda also provides users with a full set of DCS, MCS system integrated control solutions.

> Vietnam Khoi Nguyen Paper Company, dedicated to waste paper recycling, provides a variety of packaging paper type to meet the diverse needs of customers in most areas Southern Vietnam.

> The project includes one packaging production line and its public supporting works.

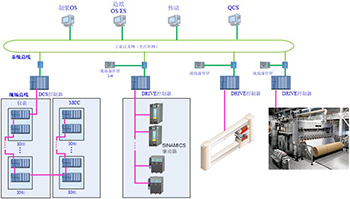

> Gaoda also provides users with a full set of DCS, QCS, steam system, Drive system, MCC, bridge, cable configuration and control solutions.

> Vietnam Miza Corporation, dedicated to waste paper recycling and packaging paper products, provides packaging paper for packaging plants in most areas Northern Vietnam.

> The project includes one packaging production line.

> Gaoda also provides users with a full set of DCS, QCS, steam system, Drive system, rewinder system configuration and control solutions.

> Indonesia SPS Group, located in the second largest city Surabaya, is a leading pulp and papermaking manufacturer in Indonesia, which its toilet paper yield more than 110000 tons per year. Since 1995, its expertise and experience have made the group one of the second largest thin paper manufacturers in Indonesia. Its capacity of packaging paper production line is also in the leading position in Indonesia.

> Yunnan Yunjing Forestry and Pulp Mill Co., Ltd. is the first forest and paper integrated domestic enterprise. being a leading enterprise in Yunnan forestry and agricultural field, it has 250,000 tons / year pulp production line, 30,000 tons / year high-grade household paper production line, and 1.1 million mu of industrial raw material forest base. It's a successful upgrading case for us to help customer in DCS alkali recovery field which being unstable in a long time.